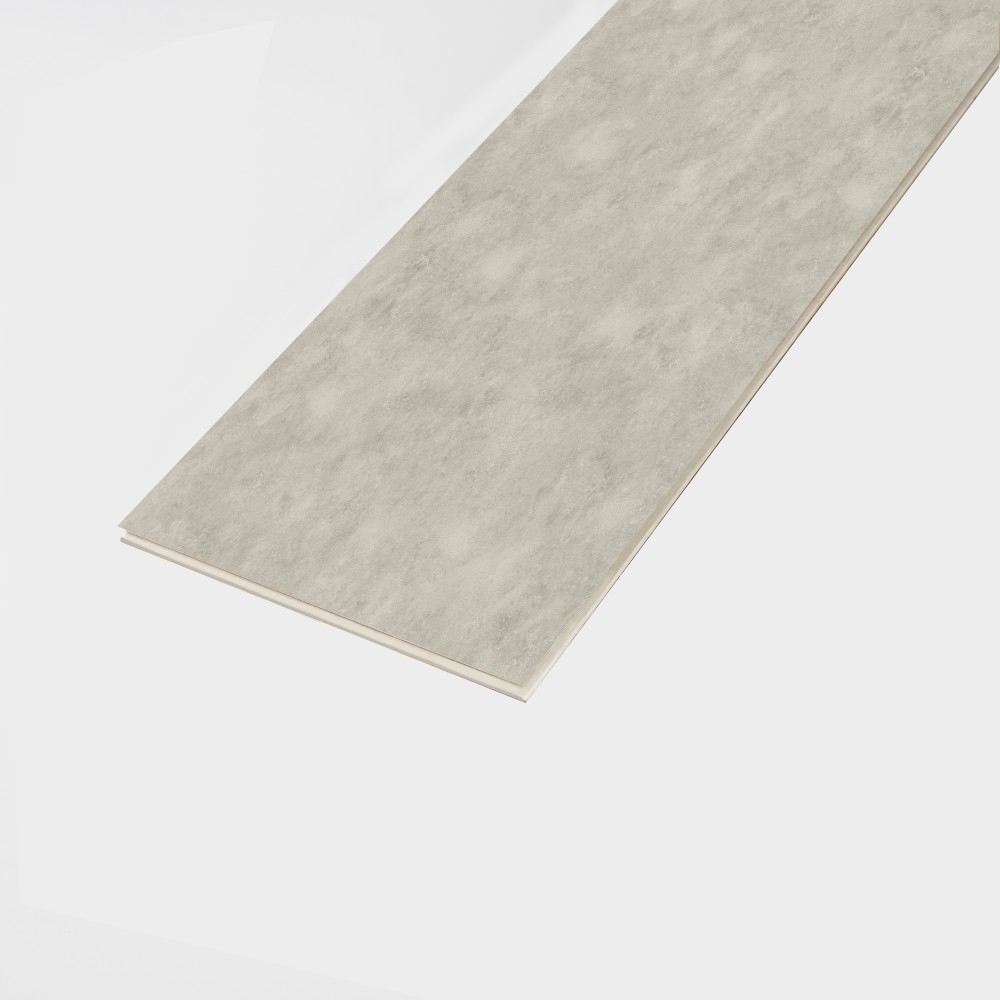

SPC Flooring (Stone Plastic Composite) is a next-generation vinyl flooring made from a combination of natural limestone powder, polyvinyl chloride (PVC), and stabilizers. It’s engineered to offer unbeatable strength, stability, and water resistance — making it one of the best flooring choices for both residential and commercial use.

Key Features of SPC Flooring

✅ 100% Waterproof – Perfect for kitchens, bathrooms, laundry rooms, and basements.

✅ Highly Durable – Resistant to dents, scratches, and daily wear & tear.

✅ Fire & Slip Resistant – Designed with safety in mind.

✅ Stable Under Temperature Changes – Doesn’t expand or contract like wood.

✅ Low Maintenance – Just sweep and mop — no polishing or waxing needed.

✅ Realistic Look & Feel – Mimics hardwood, stone, or tile with textured finishes.

✅ Click-Lock Installation – DIY-friendly, no glue or nails required.

✅ Eco-Friendly – Free from harmful chemicals and low in VOC emissions.

Here are a few points to consider: